When you pick up a fresh bag of spinach, a box of strawberries, or a pack of carrots at your local grocery store, it’s easy to assume they were harvested recently and brought directly to the store. But behind the scenes is an intricate cold chain system—and Facilities Management Group, LLC (FMG) is helping lead the charge in keeping that system efficient, innovative, and reliable.

From mobile ice generation to rapid precooling equipment, FMG plays a vital role in protecting perishable products at one of their most vulnerable stages: right after harvest.

What Is Precooling, and Why Does It Matter?

Precooling is the process of rapidly removing field heat from freshly harvested produce before it enters cold storage or distribution. Without proper precooling, fruits and vegetables can deteriorate quickly—leading to food loss, safety risks, and reduced profits for growers and distributors.

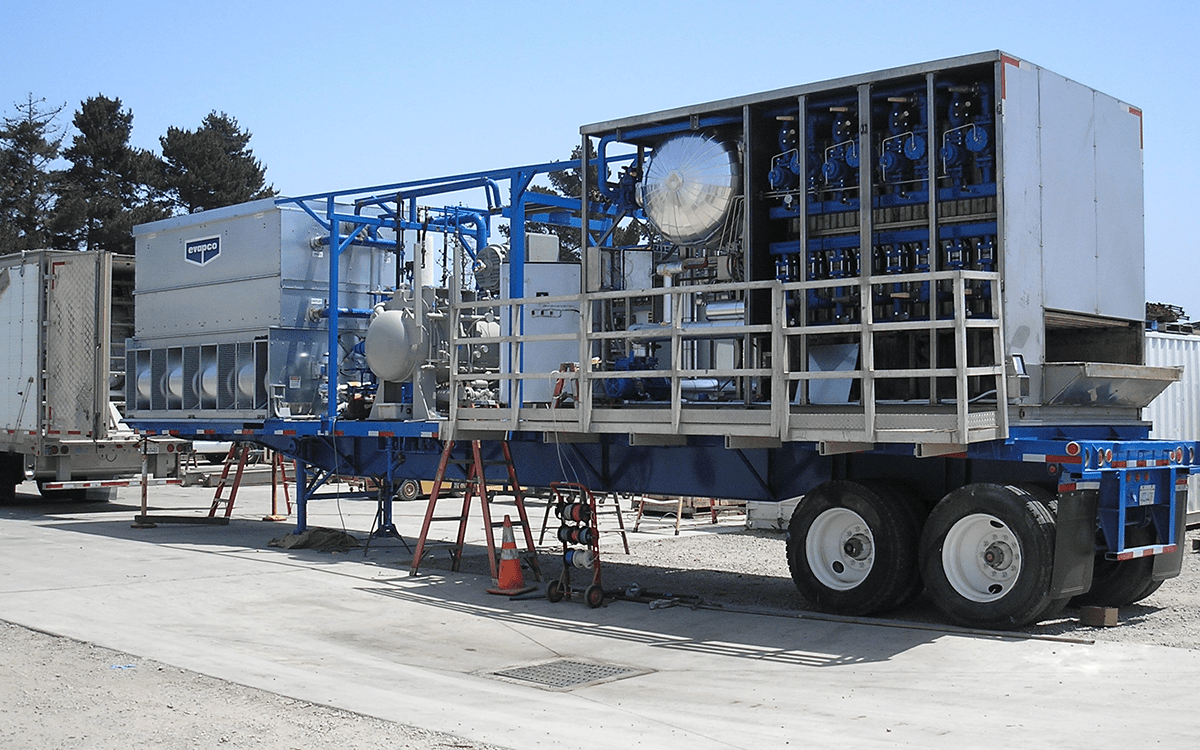

That’s where FMG comes in. Our state-of-the-art mobile precooling units make it possible to bring advanced cooling technology directly to the field, loading dock, or packhouse. This flexibility helps producers reduce waste, preserve quality, and meet rigorous food safety standards.

Why Cold Chain Logistics Need Mobile Solutions

Traditional cold chain logistics rely heavily on stationary infrastructure—large refrigerated warehouses, long-haul cold trucks, and processing plants. But agriculture doesn’t always happen on a schedule or near centralized facilities. Unpredictable harvest times, labor shortages, and climate-related challenges demand on-demand cooling solutions.

FMG’s mobile ice generator systems are designed to meet that need. Our equipment enables rapid, flexible cooling that bridges the gap between harvest and storage—where the risk of spoilage is highest. This agility helps maintain the integrity of fresh produce throughout the supply chain.

Reducing Food Waste Through Innovation

Up to 40% of the food grown in the U.S. is wasted. A large percentage of that loss occurs before the product even reaches a retailer. FMG’s equipment is helping reduce that number by ensuring produce is cooled quickly and consistently right after harvest—minimizing the window for spoilage and bacterial growth.

By delivering precooling at the point of harvest, FMG helps farmers and distributors:

- Extend shelf life

- Reduce shrink and rejections

- Meet regulatory temperature thresholds

- Improve overall profitability

Supporting the Cold Chain, One Farm at a Time

While massive refrigerated warehouses play a crucial role in cold storage, FMG supports the cold chain from the ground up. Our mobile equipment is used across a wide range of agricultural operations, from large-scale vegetable growers to seasonal harvesters with temporary packing sheds.

Whether you’re dealing with leafy greens, berries, root vegetables, or other high-respiration crops, our mobile precooling systems can be deployed quickly and scaled to fit your operation’s size and needs.

Dependable, Field-Proven Equipment

At FMG, our equipment is built to withstand tough field conditions and demanding harvest schedules. We pride ourselves on offering solutions that are:

- Durable and low-maintenance

- Energy-efficient

- Customizable based on your commodity and throughput

- Supported by a responsive technical team

From small specialty farms to large packing operations, FMG’s flexible technology helps improve cold chain performance where it matters most—at the start.

If you’re looking for a portable, powerful solution to help your crops stay fresher longer, FMG is here to help. We understand the critical role that timing, temperature, and technology play in delivering safe, high-quality food to the market.

Explore our full line of precooling solutions at fmgsolution.com or contact us today to learn how we can support your next harvest.

Recent Comments